Snow retention system is an important element of the entire roof safety, which prevents the avalanche of snow down the slope. Installation of snow guards is a must if there is a lot of snow in your area, the slopes are steep or the roof is covered with metal tiles, corrugated board or other material with a smooth glossy coated metal surface.

Where does the snow retention system go?

Fresh snow is very powdery and soft. But after a few days it becomes denser, and as soon as the temperature goes over zero, crust appears and the snow mass begins to freeze, eventually turning into a piece of ice. Every year we see this process in nature and on the roads, and the same happens on the roof. Even if the roof is well insulated, heat still goes through the entire roof area, which accelerates the melting of snow and turns it into ice. The exception is well-ventilated cold roofs, when the air temperature in the under-roof space is practically the same as outside of the building. In the long term, frozen snow falls off the metal roofing . This usually occurs when a critical mass of snow and ice load is reached or during thaws, when the snow melts, forming a thin layer of water between the roofing and the snow cover.

The mass jumping off the metal roof looks like a layer of snow or a block of ice and often weighs hundreds of pounds. Add to this the strength and speed that the snow and ice mass gains as it slides down the roof surface. It is easy to imagine the consequences if a car, tree, person, air conditioner or satellite dish are on the way. Installation of an effective snow retention system on the entire roof is designed to prevent this damage. They either keep snow in place or cut the sliding frozen snow mass into safe small pieces. Thanks to this, roof snow and ice gradually descend from the slopes without posing any threat. Since it is not always possible to install snow guards along the entire length of the eaves, we give a list of the most dangerous areas where their installation is required:

- the place above the entrance to the garage;

- over all entrances to the house;

- over wires (electric, television, internet cable);

- at all levels of multi-level roofs;

- on slopes that are above paths, sidewalks, roads and other places where people can walk, pass or park cars;

- over the canopy, gazebo, fence.

In addition, in order to preserve the entire roof and extend the service life of the roof itself, use of a snow guard system is required:

- Over ventilation pipes, deflectors, chimneys to avoid damage. In these areas accumulated snow inevitably sweeps in the wind near any protruded elements on the roof. Installing a snow guard reduces the size of the snow heaps and reduces the risk of leakage.

- Above the dormer windows so that snow does not sweep them. This allows the glass for a longer time – there is a lot of dust, ice crystals and other abrasive particles in the lower layer of packed snow. Therefore, the sliding layer of snow can scratch the glass of the roof window if there is no obstacle on its way.

- Above satellite dishes, antennas and other rooftop equipment. In areas where snow can damage trees, bushes, and supports for plants.

- The use of several rows of snow guards is required on a long slope or in regions with a heavy snow load. If the mass of snow is very large, then during the descent, the layer can gain enormous mass and it will literally rip off the snow guard. Installing snow guards on the roof in several rows prevents this. Usually they are mounted with a spacing of 6 feet from each other.

You do not need to install snow guards on roof slopes, where the descent of snow down the pitch does not pose any threat. Also, snow guard is usually not mounted on very steep roof pitch – the snow and ice simply do not linger on such pitch.

Snow guard spacing on the metal roof

Most often, snow retention system is mounted on metal roofing. Firstly, because this type of roof is very popular in general. Secondly, due to the smooth surface and high thermal conductivity, the snow and ice mass slides off any metal roof pitch much more rapidly than from rough textured roof areas. This applies to metal tiles, but also to corrugated profile, classic standing seam roofing panels and even premium copper tiles.

Before installing the snow retention system, you need to make a snow guard layout, i.e., mark snow retention placement and snow guards pattern on the roof drawing. This will indicate the location of each snow guard, the distance between them and the eaves overhang, as well the spacing between other elements of the roof. If the installation of snow retention systems is carried out in two or more rows, the distance between them must also be marked on the layout. Snow guards are attached to the crate. Therefore, when creating a snow guard layout, it is imperative to take into account the crate spacing as well. Some types of snow guards can only be secured to a solid crate, that is why it is better to plan their installation in advance – at least at the stage of when the rafter system is put up.

Tubular snow guards are the most popular and effective type of snow retention system. One snow guard consists of two or three pipes with a diameter of up to 1″ and several brackets. The distance between the brackets depends on the snow load in the region and the slope of the roof, but usually does not exceed 35 inches. When the snow melts, the tubular snow guard brakes the snow mass, and the whole chunk is gradually squeezed under its own weight between the pipes. As a result, the snow and ice does not remain on the roof for the whole winter, loading the supporting structures, but is cut into small, safe pieces. To prevent the cornice from breaking under the weight of the snow mass, the installation of snow guards must be performed above the cornice overhang. The first row is usually installed above the load-bearing wall. According to the rules, tubular snow guards should only be attached to a solid crate. But if we talk about the existing roof and there is no way to do this, it is advisable to install snow guards on existing bars. In this case, the distance between the boards of the crate and their width should allow the brackets to be securely fixed on both sides. No screw should be exposed or suspended in the air.

On long sections of slopes, the installation of snow guards is often done with specifically designed pipe extensions. For this, the “mortise and tenon” technology is used: on one side the tubes are narrowed, which makes it easy to connect them to each other. The connected tubes must be fixed with bolts. The second and subsequent rows of snow guards are installed in the same way.

A separate point should be made about the standing seam panel. For this type of roofing it is recommended to use only a tubular snow guard retention system. They must have special brackets that fit directly on the fold where they are secured with a clamp. This method of installing snow guards maintains the tightness of the roof and at the same time is reliable: the thickness of the sheet on the folded joint is at least four times greater than on other sections of the roof.

There are certain cases when installing a two-pipe snow guard is the only right solution. In heavy snowfall, in particular, when wet snow accumulates on the roof, a simple plastic snow guard can simply bend over and fall off. Tubular snow guards are recommended by experts because they divide snowfall into at least two parts, ensuring safety for people and landscape under the roof. In this case, the fastening of the snow guard must be performed only along the perimeter of the roof and over the roof windows.

The use of such a system greatly reduces the kinetic energy of the sliding snow and its destructive power. As a result, several problems can be solved at once: the snow comes off the metal roof under the influence of its own heavy weight, and in the event of a fall, it no longer poses a threat to others.

Optimal snow guard spacing

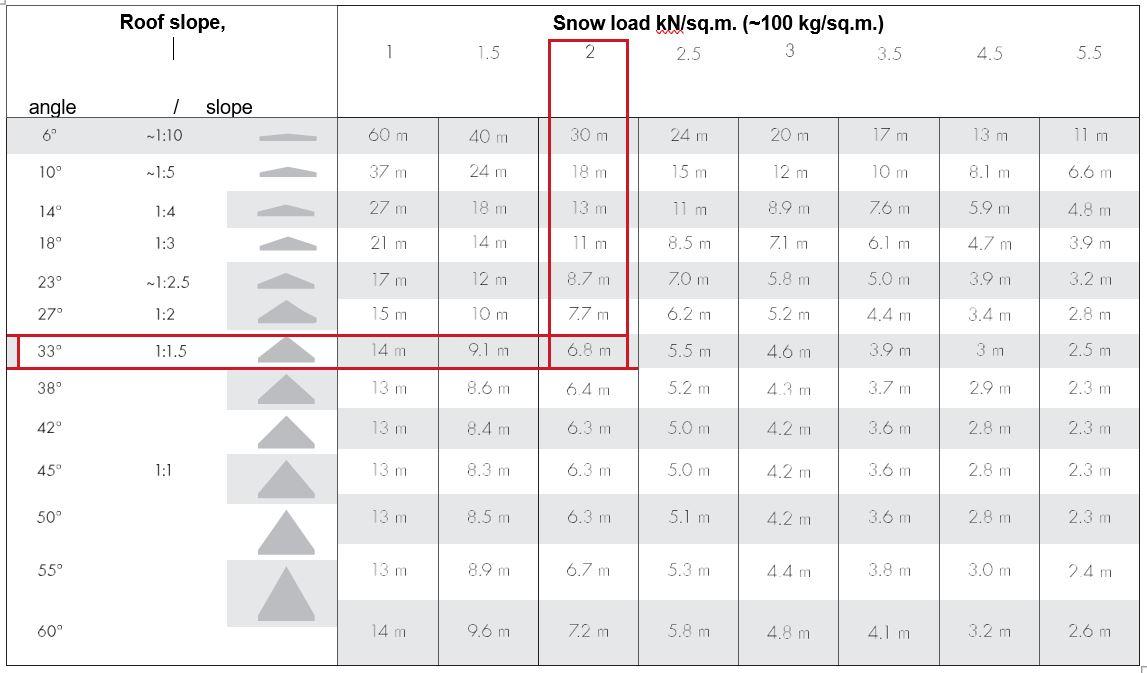

According to the standard design, the optimal distance between the brackets for the snow holders is calculated based on the planned snow load in a particular region. This approach is determined by the need to redistribute the load from the snow retainers to the load-bearing walls of the building roof area. If we neglect this condition, then in the long term the excessive amount of snow and ice will accumulate on the overhangs. This mass will operate according to the principle of a lever, thus breaking the roof structure.

The pattern of tubular snow guards installed along the perimeter of the roof area must be continuous. In cases where the length of the slope exceeds 20 feet , it is allowed to install 2-3 rows of snow retention devices.

Devices for keeping snow on metal roofs should be installed flush with the load-bearing walls, so that the snow mass will only press on the section of the roof located above the eaves. At the same time, 25-40 inches should remain from the overhang of the eaves to the load-bearing wall. It is mandatory to install snow guards above the attic windows. In these places, a continuous crate is required for the installation of pipe snow guards.

Fasteners and adapters for snow guards allow you to adjust the number of rows and pipes. Please note that the main load from the snow always falls on the fasteners. Therefore, the roof covering must be robust enough to withstand the same load. As a result, the step between the fasteners can be increased to 47 inches. When the slope length is more than 20 feet, the fasteners must be mounted in 35 inches increments. If the slope length is in the range of 4-17 feet, then the fasteners can be set at a distance of 23,6 inches.

If the slope of the roof is 30º it is required to have two-tube snow guards installed.

Let's summarize

In the article, we told you where on the roof you need snow guards , how to properly install them on metal panels and other roofing. Snow guards are required above all entrances to the house, the entrance to the garage, on multi-level roofs, on slopes, the snow from which can damage things or injure people. In addition, it is advisable to place them above roof windows, pipes and elements of the roofing infrastructure. Tubular snow guards are best for metal roofs as they are able to keep the snow load and work like snow cutters.